Request A Quote

Our business is most valuable when it helps our customers. Please fill out the form with as much detail as possible so we can respond with the most helpful solution.

Yuji mass produces fourth generation HFO blowing agents to support businesses’ transition to sustainable alternatives. Established in 2005 and with multiple manufacturing sites, our team of doctoral experts strive to deliver advanced fluorine chemical solutions with excellent performance qualities to our global partners. Choose Yuji as your supplier of HFO foam blowing agents for your spray foam insulation, polyurethane (PU) foam, or polystyrene foam development.

A blowing agent, or foaming agent, is a substance that can create cellular structures by the process of foaming in a range of materials that go through phase transitions or hardening, such as polymers, plastics, and metals. Usually, they are used when the blown material is still liquid.

Foam blowing agents encompass a wide variety of applications, including:

The blowing agent used can be liquid or gas that is dissolved in the foam precursors and expands to form the foam once it is injected or sprayed and the foaming reaction begins. These agents are used in spray foam insulation, which can be found inside the walls of your home or business. The chemicals used to create the insulation has been proven to be damaging to our environment, so in coordination with regulations businesses have had to transition to a more eco-friendly option: foam blowing agents based on HFO chemistry.

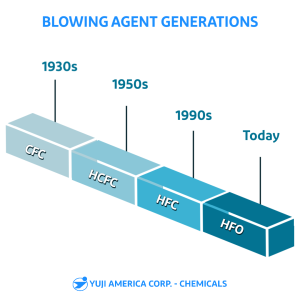

HFC alternatives have been developed as a response to global warming concerns. This diagram breaks down the different generations of fluorocarbons that were utilized as blowing agents up until the phasedown of HFCs and the introduction of HFO as a sustainable alternative.

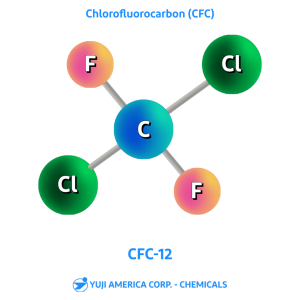

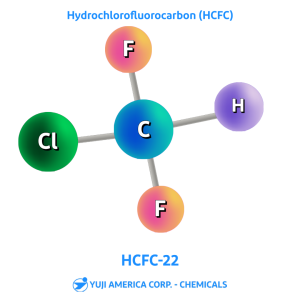

Like all of modern technologies, blowing agents have undergone rigorous testing, trials, and different formulations to develop what we now have today. The first generation of blowing agents used in spray foam are chlorofluorocarbons. Due to their damaging characteristics, CFCs were outlawed in the 90s with a GWP value of above 4,000 and an ODP of 1. Hydrofluorocarbons (HCFCs), the second generation, were banned in 2005 due to their high GWPs (above 700) and ODPs.

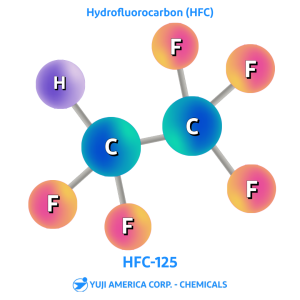

Due to their destructive qualities, hydrofluorocarbons, or HFCs, the third generation of blowing agents, are also currently being phased out. The most recent laws that forbid HFCs from being used in spray foam insulation aim to lessen the usage and emission of heat-trapping substances that can contribute to global warming.

HFOs are the fourth generation alternatives to previously widely used HFCs (hydrofluorocarbons)- which are currently being phased out as decided by the Paris Agreement & the Kigali Amendment of the Montreal Protocol. The 1990 Montreal Protocol, which prohibited ozone-depleting compounds, led to the replacement of numerous chlorofluorocarbons (CFCs) and hydrofluorocarbons (HCFCs) as blowing agents in the foaming industry. Gaining much more popularity in the chemicals sector, are compounds based in HFO (hydrofluoro-olefin) chemistry, which have zero ozone depleting potential (ODP) and low global warming potential (GWP). Transitioning to HFO foaming agents is a crucial step in decreasing the negative climate impact in the building and construction materials sector.

| CFC | HCFC | HFC | HFO | |

| Governing Regulations |

Montreal Protocol – Enforced in 1989

|

Kyoto Protocol – Enacted in 1997

|

Kigali Amendment – Adopted in 2016

|

|

| Several halogenated hydrocarbons are identified as ozone depleting substances due to containing chlorine. | Seven greenhouse gas categories targeted for reductions; carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), hydrofluorocarbons (HFCs), perfluorocarbons (PFCs), sulfur hexafluoride (SF6), nitrogen trifluoride (NF3). | Amended action to the Montreal Protocol to ensure HFC consumption and production. In response, industries have been gradually looking for sustainable HFO alternatives. | ||

Industry Application Usage Example |

||||

| Blowing Agent |

R-11 R-113 |

R-141b

|

R-134a

R-245fa R-365mfc |

HFO-1233zd(E)

HFO-1234ze(E) HFO-1336mzz(Z) |

| Aerosol Propellant | R-114 | R-134a

R-152a |

HFO-1234ze(E) | |

| Refrigerant | R-11

R-12 R-13 R-113 R-114 R-115 |

R-22

|

R-32

R-125 R-134a R-245fa R-410A R-404A |

HFO-1234yf HFO-1234ze(E) HFO-1233zd(E) |

| Solvents | R-11

R-13 |

HFO-1233zd(Z) | ||

|

|

|

|

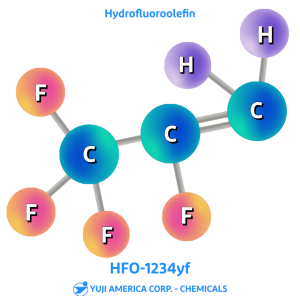

Featuring low GWP and low ODP, unsaturated organic compounds containing hydrogen, fluorine, and carbon are known as hydrofluoroolefins (HFOs). They are utilized foam insulation industry with adoptions underway for its usage in more applications- such as refrigeration, aerosols, food industry and specialty working fluids for example.

The distinction between HFOs and HFC is the olefin, a term that simply denotes the presence of a double carbon bond inside the molecule. The difference is in the way the atoms are bonded because the atoms are the same as in CFC, HCFC, and HFC. Because of this olefin property, HFO molecules have a brief atmospheric lifespan, making them substantially more environmentally friendly than their predecessors. The atmospheric lifespan of a chemical and its global warming potential (GWP) are intimately correlated. The double bond makes the molecules less stable and leads to fast decomposition in the atmosphere which is just a few days instead of years and decades as in the case of HFCs.

In order to understand blowing agents, it’s important to understand why the spray foam industry relies on them to keep our spaces thermally insulated. Climate friendly blowing agents powered by HFO chemistry is the best option available and are increasingly gaining popularity for foam and adhesive applications.

Excellent-performing insulation reduces heat transfer to increase energy efficiency. Building insulation lessens heat gain or loss, enhancing tenant comfort and perhaps lowering energy expenditures. It minimizes heat gain and aids in maintaining precise temperature control during cold and chilled storage and transportation.

The demand for thermal insulation has significantly increased as the importance of buildings in lowering energy dependence and greenhouse gas emissions has come to light, which is consistent with these difficulties with energy performance in both new construction and rehabilitation. Energy consumption can be greatly reduced by retrofitting insulation into the building shells of existing structures. This means that having great spray foam insulation based in HFO chemical technology can have a positive impact on utility consumption, saving you or your business money in the long run.

Excellent performing HFO chemicals, such as Yuji’s HFO-1336mzz(Z), helps create insulation foam and foam products that helps builders and roofers achieve energy efficiency goals, cost savings, and greenhouse gas emission reductions. The HFO solution gives the same or higher performance with a drastically lower global warming potential than competing solutions employing hydrofluorocarbon foam blowing agents, thus providing a more sustainable alternative.

| Spray Foam Insulation | Foam insulation for low, medium, and high density residential and commercial building construction. |

| Rigid Polyurethane Foam | Foam insulation for roof, walls, windows, doors, air barriers, etc. |

| XPS Foam Products | Foam insulation for walls, ceilings, under concrete slabs, inverted roofs, etc. |

Spray foam, adhesives, and insulation industries all use blowing agents. They enable materials to deliver heat resistance, foam, and/or expand, as in the case of applications in spray foam insulations, air conditioning or refrigeration systems. To achieve excellent performance, it is imperative to consider all the necessary properties of the foaming agent.

Because of these environmental regulations, the building and construction industry, residential and non-residential, and the roofing sectors, are directly impacted. Spray foam and refrigerant businesses are propelled to work with the formulation of their products in order to meet international standards

We work in conjunction with industry leaders, manufacturers, and our internal team of experts, Yuji develops the next generation chemical solutions needed for your business. Our product line of blowing agents with low greenhouse effect index directly supports the industry’s transition to sustainable alternatives.

Innovative chemical technologies power the world, that’s why Yuji’s advanced fluorochemicals are perfect for your product development. The protection of our environment and society is at the center of our vision as we imagine the chemical solutions that will shape the future. As impacted industries make changes towards sustainable alternatives, we will definitely see the rise and importance of HFO chemical solutions in the future. Yuji’s HFO blowing agents offer excellent performance qualities while featuring a low greenhouse effect index, making our chemicals ideal for your product development.

|

HFO-1336mzz(Z) is ideal for polyurethane (PU) foam and spray foam insulation applications. Ideal eco-friendly alternative for HFC blowing agents with zero ozone depletion potential (ODP) and low global warming potential (GWP). Non-flammable, provides high efficiency, and thermal stability for your foam product development. |

LEARN MORE |

Previous Dielectric Insulating Gas

Next Electronic Solvents

Our business is most valuable when it helps our customers. Please fill out the form with as much detail as possible so we can respond with the most helpful solution.